Description

Description

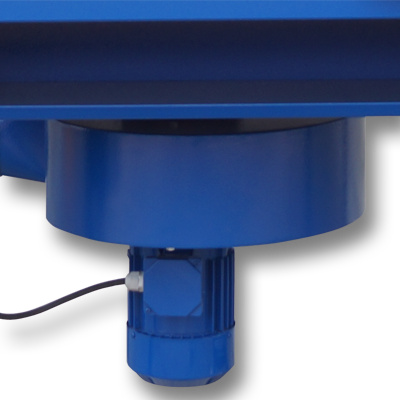

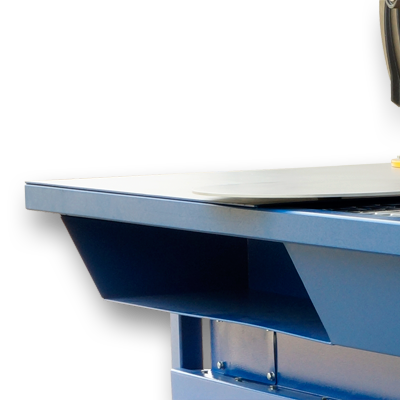

The SF-1000 welding table is a workstation equipped with a capture, exhaust, and filtration system to protect against air pollution generated during workshop processes, especially welding. The table’s frame is made from heavy-duty square profiles and includes a built-in downdraft exhaust, an inlet for connecting a fume arm, and a ZWR-03 aluminum radial impeller fan unit. Individual dampers for the downdraft exhaust and fume arm allow for airflow adjustments. The captured air pollution is transported to the Crawlair filter unit, which purifies the air using a preliminary filter and a cartridge filter module. The Crawlair filter unit includes a cartridge regeneration system that can be operated manually or with an optional timer. The surface of the SF-1000 welding table is coated with conductive corrosion protection, and a grounding cable can be connected to either the left or right side of the table frame. Complete sets of the SF-1000 welding table come with a revolving table, making work on smaller elements more productive.

Applications

- heavy duty workbench with two exhausts for welding, cutting, grinding and many more for those who require reliable and long operational life time equipment

- air pollution capture with down draft and within range of fume arm

Construction

- 1000 m3/h airflow

- 1,1 kW Crawlair filter unit

- rigid, heavy duty, welded steel construction

- downdraft with-in the table surface

- easy to adjust airflow with two built in dampers (within the arm and table)

- revolving table on the table surface

- all parts powder coated (except for work surface)

- ready to work with Oskar fume arm 160 models